Our Story

Hey! Thanks for stopping by. As a violist and tinkerer, I've always been involved with creating things. This idea came during my internship at an artisan bowmaker studio as many bowmakers I talked to mentioned the issue of Pernambuco conservation and a continued limited access to music education.

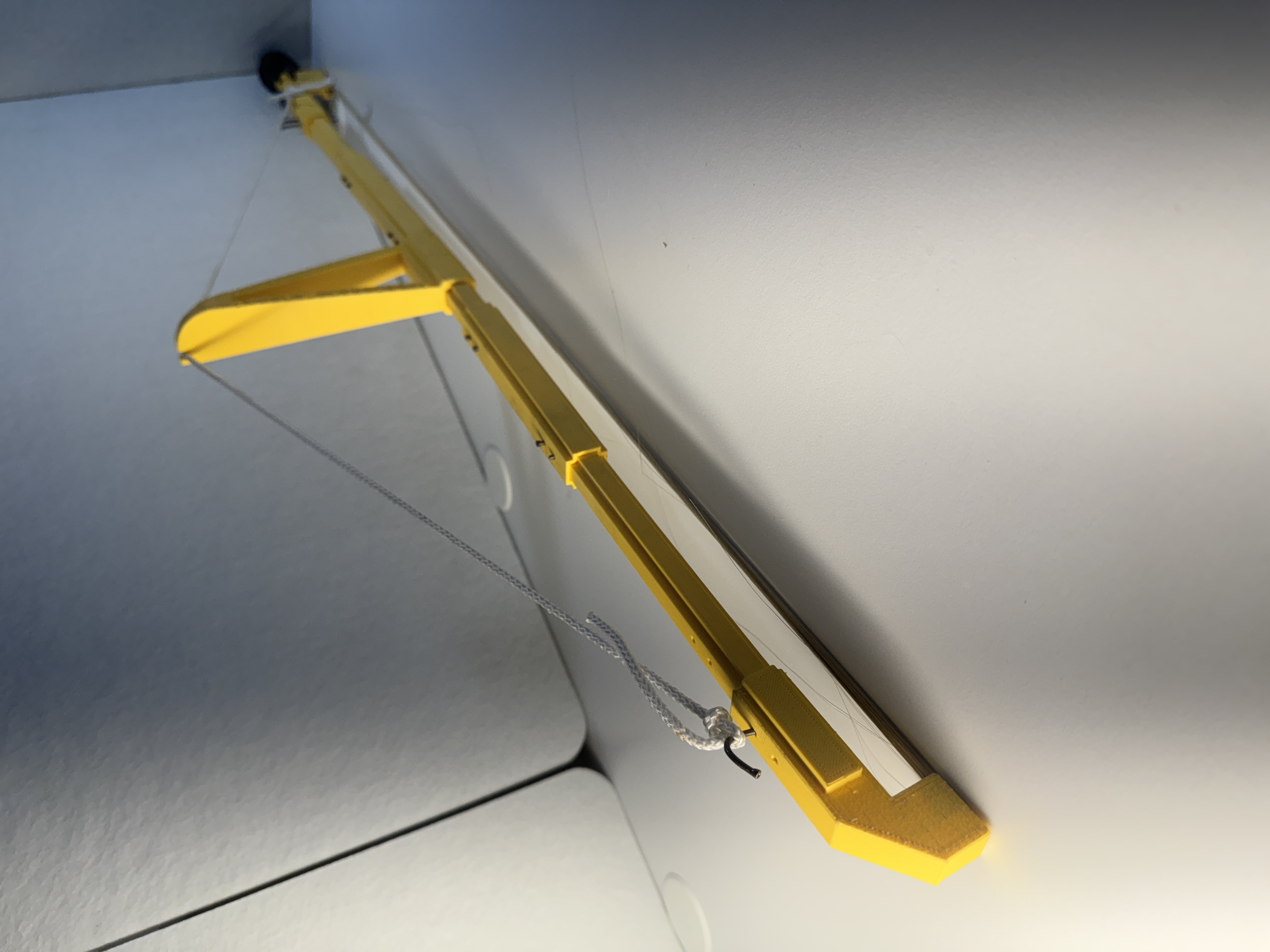

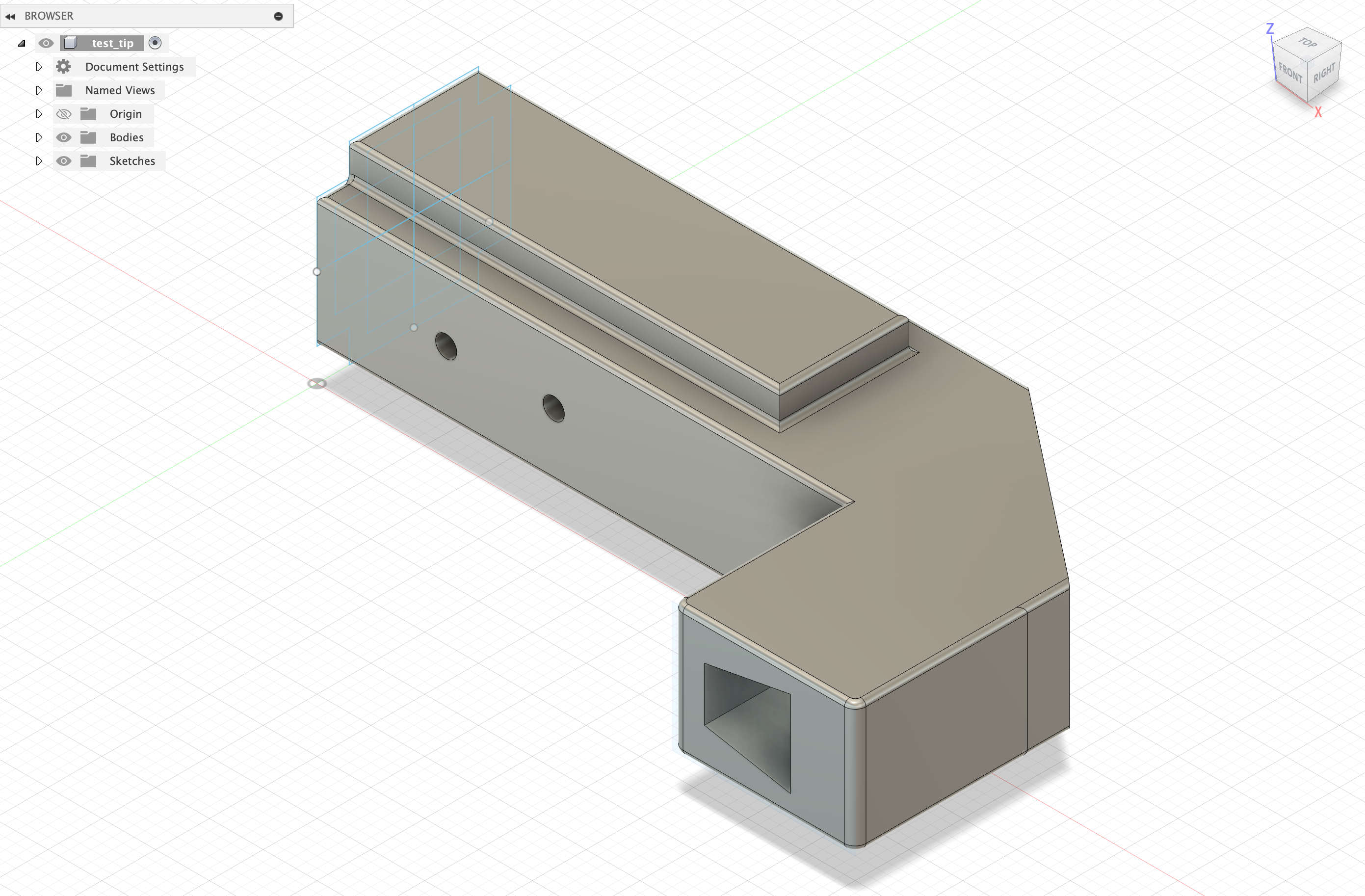

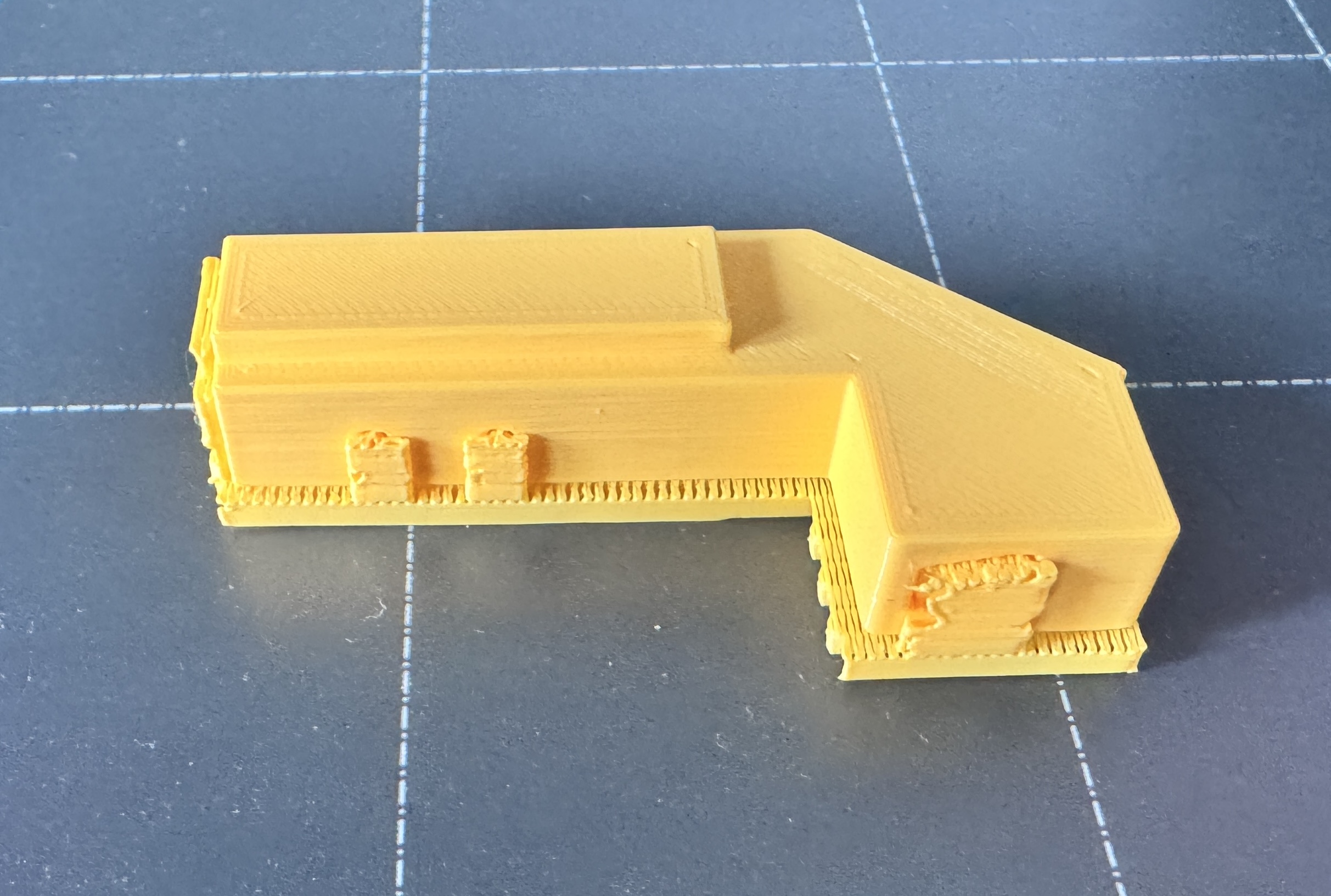

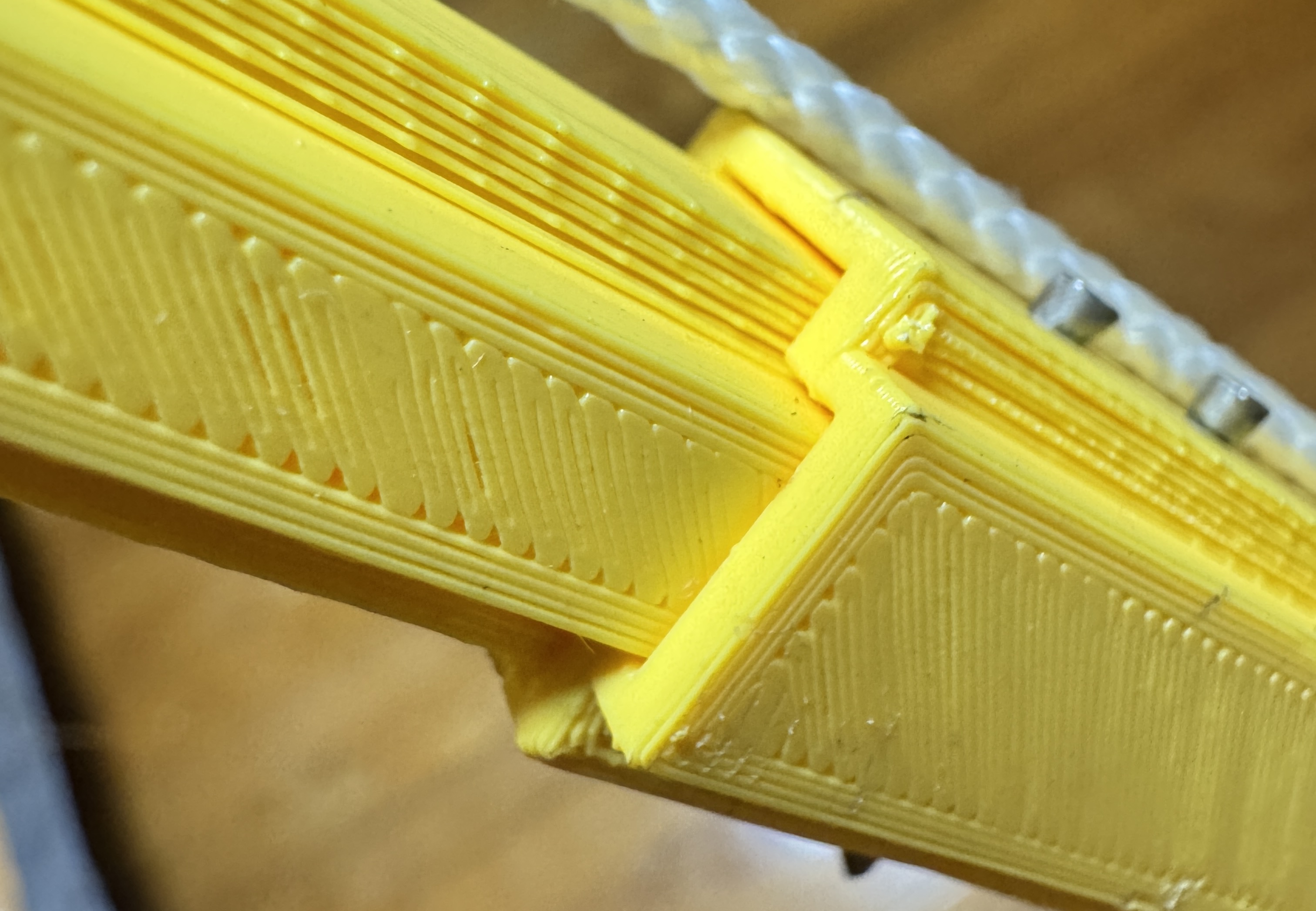

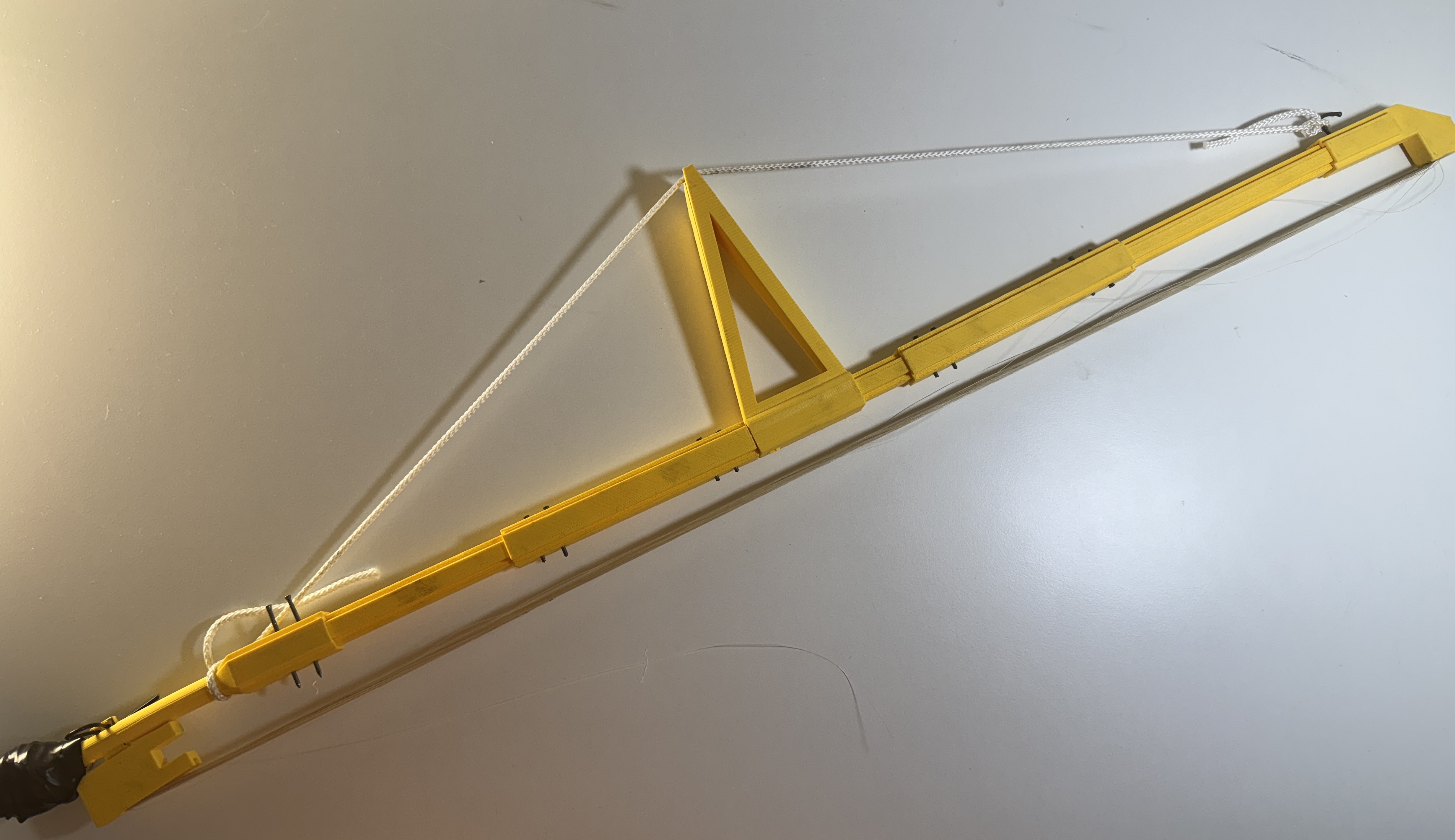

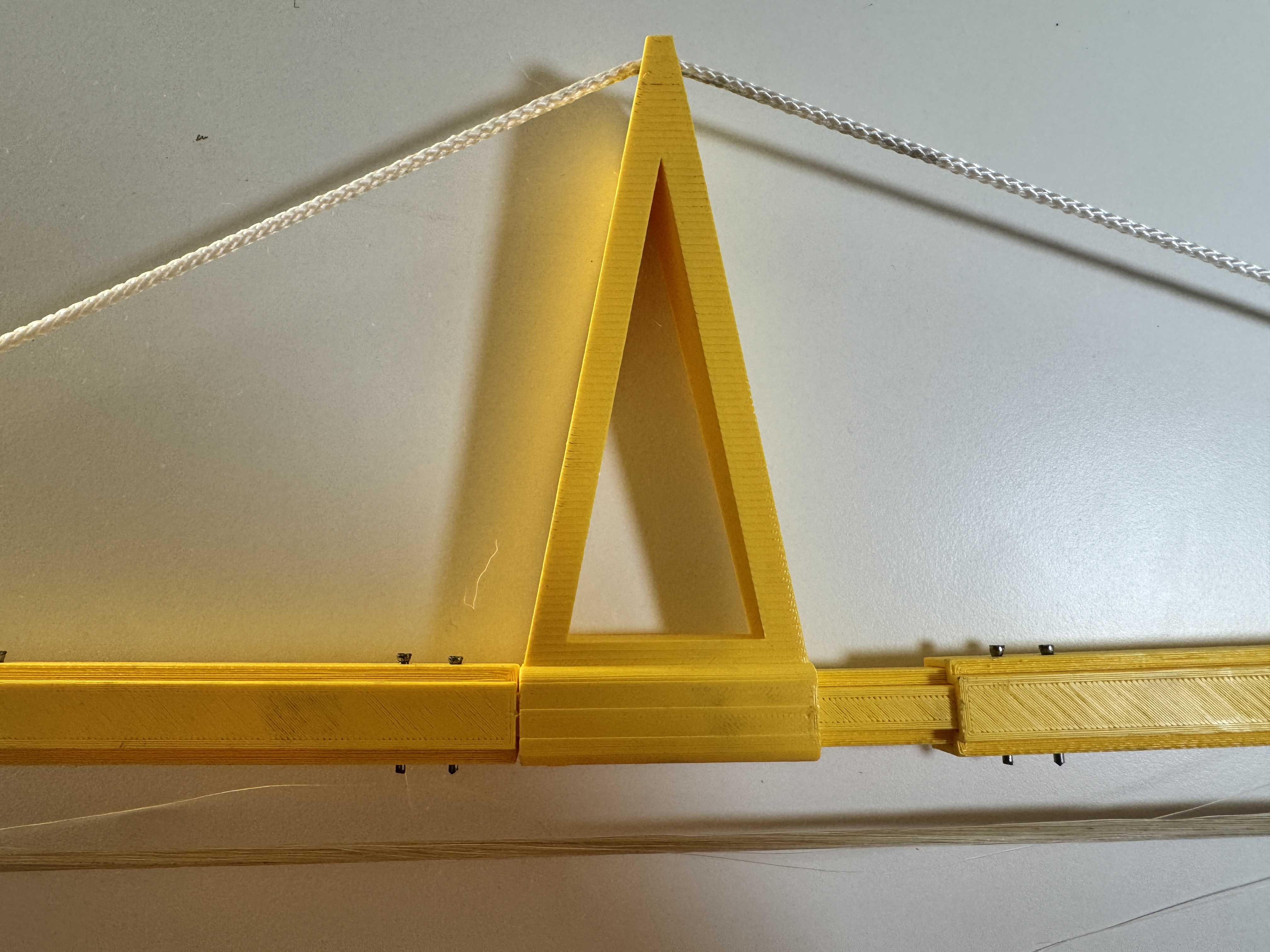

Looking online, there were so many 3-D printed instruments appearing but hardly any attempts at creating 3-D printed bows. And so the idea seemed obvious: why not try printing a bow?

With the support of bowmaker mentors and inspired by the urgency of access, I started BowLab to reimagine the bow as an affordable, reproducible, and sustainable tool. Every prototype brings us closer to a world where no student is held back by the cost of their equipment.